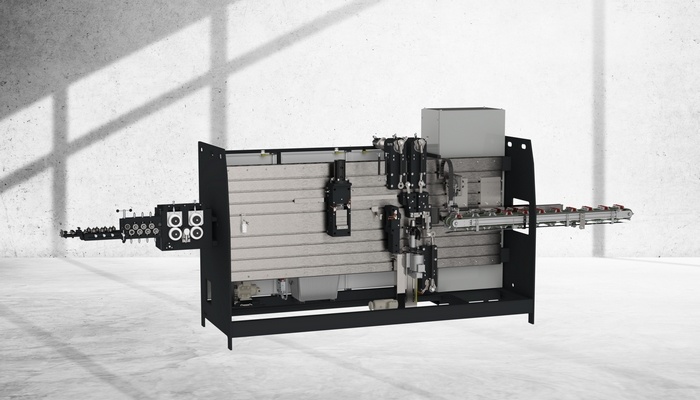

ABM 330 - Frame bending machine

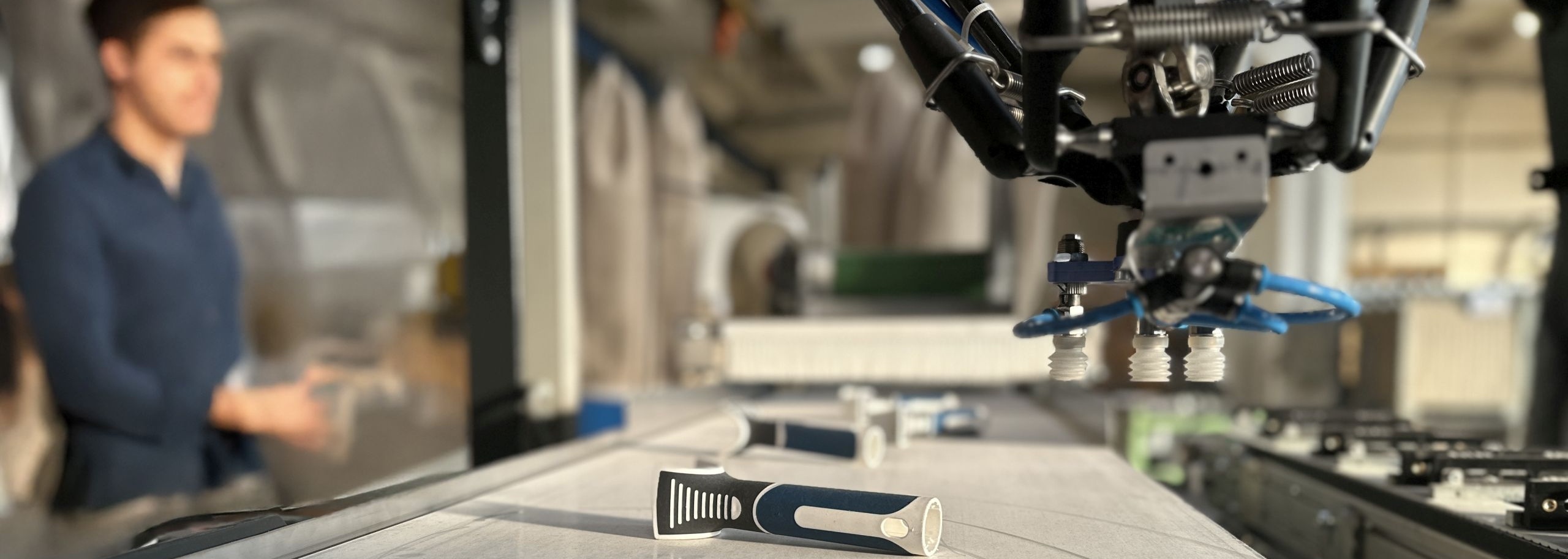

The ABM 330 is specially designed for paint roller handle production with a wide range of forms, sizes and wire diameters. Wire uncoiling via driven coil holder, wire straightening and wire pressing have been taken over from the previous machine model. Newly designed is the bending technology with three servo driven cams, effectively doubling the machine performance!

The wire is pulled off from the driven coil holder throught a double plane straightening device and length measuring system. The so called wings for holding the plastic handle are pressed, the plastic handles fed from the other side and assembled on the wire. Finally the bending process is made in 3 steps in rapid sequence and the finished paint rollers are ejected.

Characteristics

- powerful and reliable,

- universal production of all paint roller hooks,

- interchangeable unit for small hooks,

- large machine frame,

- the bending process is carried out in a very fast sequence thanks to three servo motors,

- high production capacity,

- double wire straightening rollers,

- manual or automatic feeding of handles,

- short changeover time.

The machine consists of individual stations:

- driven wire unwinding device - automatic wire feeding to the machine with continuous speed control,

- wire straightener,

- wire feed and measuring (accuracy ± 0.5 mm) - servo motor,

- wire pressing and cutting - hydraulic drive,

- wire deburring,

- bending unit - 3 servomotors,

- unit for clamping the handles on the wire,

- optional: threading unit, pricking unit, labelling unit, additional pressing.

Technical data

| Capacity | approx. 35 - 40 pieces/min. (2,100 pieces/h) |

| Wire strength | max. 650 N/mm |

| Wire diameter | 6 - 8 mm (0.24 - 0.32"), galvanised steel wire, other diameter on enquiry |

| Wire coil | max. 1,500 kg |

| Types of handles | to customer requirements |

| Hydraulics | 20 MPa |

| Air pressure | 0.6 MPa |

| Air consumption | max. up to 17 m³/h |

| Sound level | 75 dB - measured at distance of 1 m to machine |

| Height | approx. 2,200 mm |

| Weight | 3,900 kg |

| Area required | approx. 7,000 x 2,000 mm |

| Electrical connection | 3 x 400 V/50 Hz, N/PE, 17 kW |