ABM 310 - Frame bending machine

The ADMV 310, the predecessor of these latest machine models, is still available despete its lower output. It is ideal for smaller companies wirh lower production requirements. The bending process is normally performed in thre bending and movig steps. The bending unit is also servo-driven.

Process

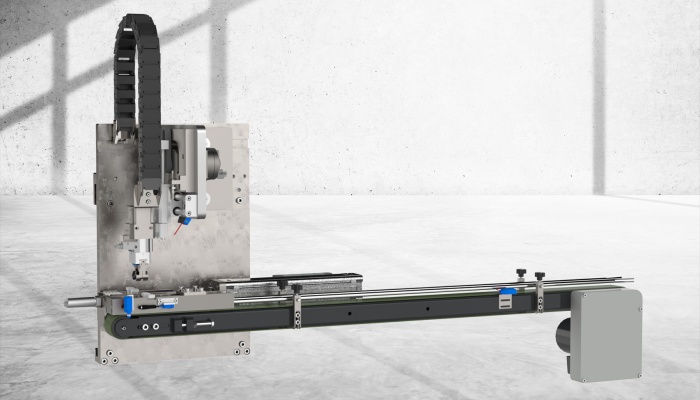

The wire is taken-off from a driven coil holder through twin-plane straightening rolls and into the feeding and length measuring system. The wire is fed and measured by two pairs of grooved rolls. One pressing device driven by hydraulic pump to make marks for fixation in handle. Bending form of wire is freely programmable by servomotor. The wire frame is chamfered from both sides of wire. The machine runs in fully automatic cycle with production output of 2.100 – 2.400 pieces per hour as a maximum.

Features

- For two wire diameters 3,40 and 4,00.

- Freely programmable wire shape.

- Chamfered from both sides.

- Just the same pressing marks like on the delivered samples.

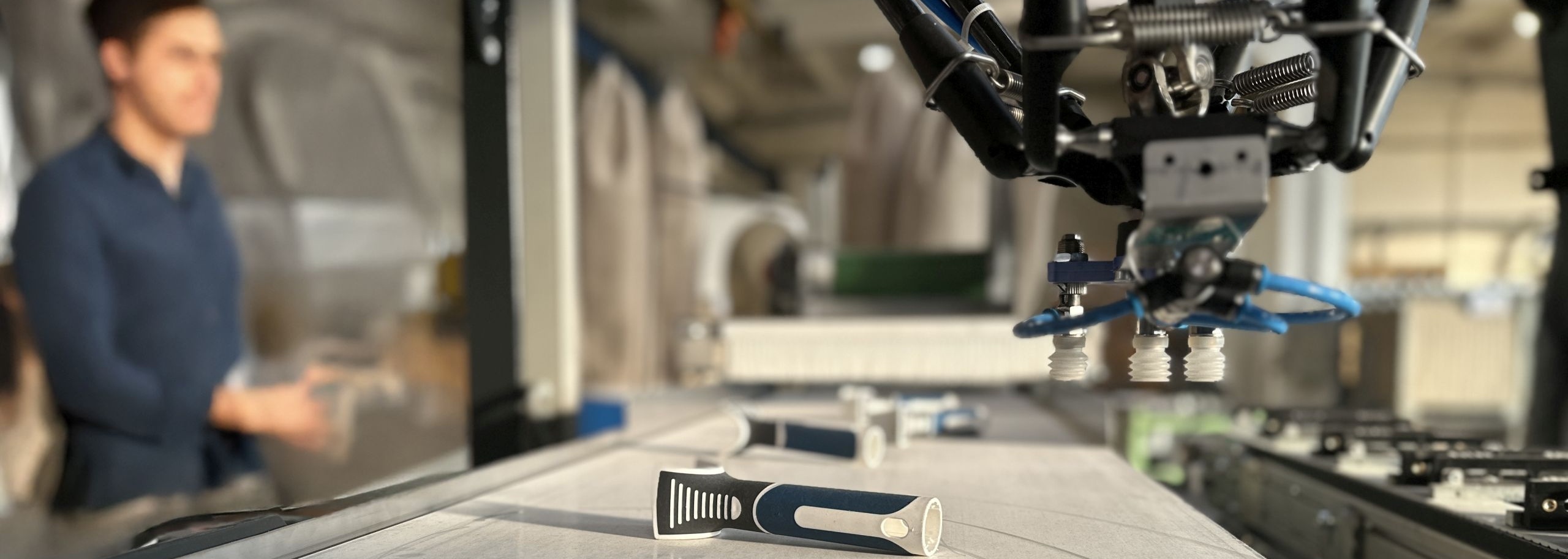

- Machine will be prepared for later assembling of the plastic handles by means of conveyor belt on which the operator places the handles in an oriented way.

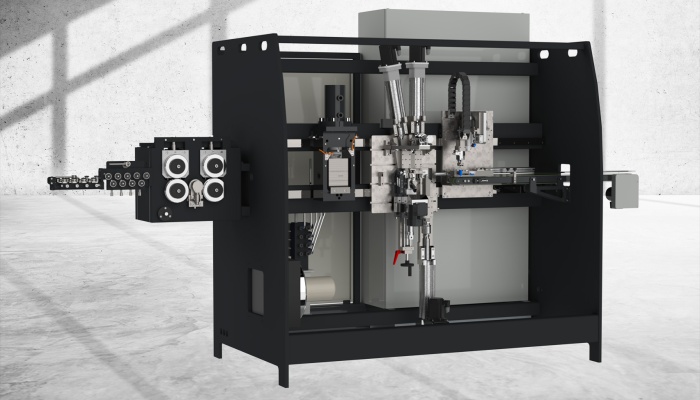

The ADMV SM machine consists of

- powered wire coil holder

- straightening device

- wire feeding device – servo motor

- pressing and cutting device driven by hydraulic

- chamfering devices from both sides of wire frame

- bending unit – 3 servo motors

Technical data

| Capacity | approx. 2,400 pieces/h |

| Wire strength | max. 650 N/mm |

| Wire diameter | 3,4 - 4 mm, galvanised steel wire, other diameter on enquiry |

| Wire coil | max. 1,500 kg |

| Types of handles | to customer requirements |

| Hydraulics | 20 MPa |

| Air pressure | 0.6 MPa |

| Air consumption | max. up to 17 m³/h |

| Sound level | 75 dB - measured at distance of 1 m to machine |

| Height | approx. 1,800 mm |

| Weight | ca 2,000 kg |

| Area required | approx. 7,000 x 3,000 mm |

| Electrical connection | 220/380 V/60 Hz, 12 kW |