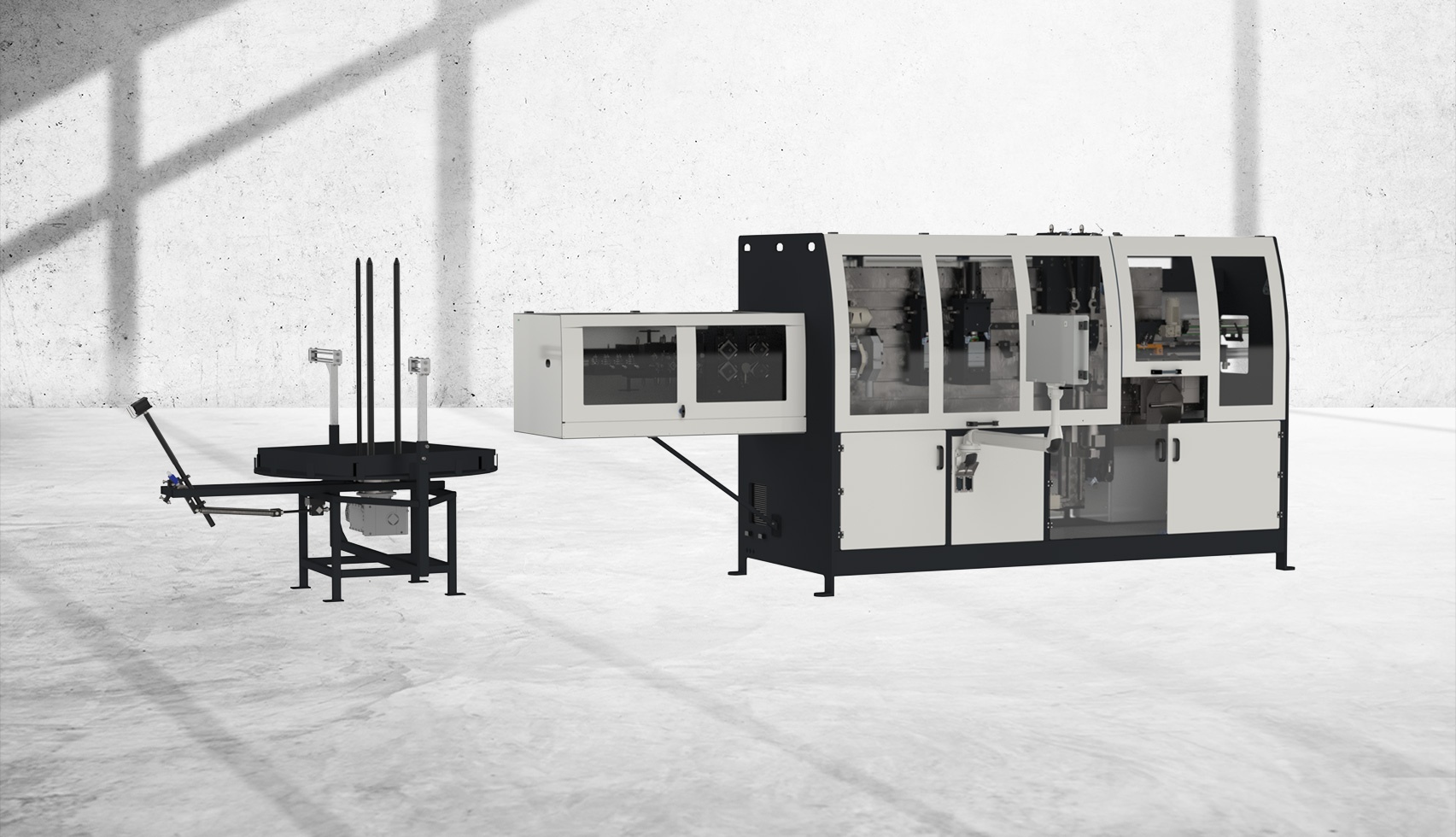

ABM 320 - Frame bending machine

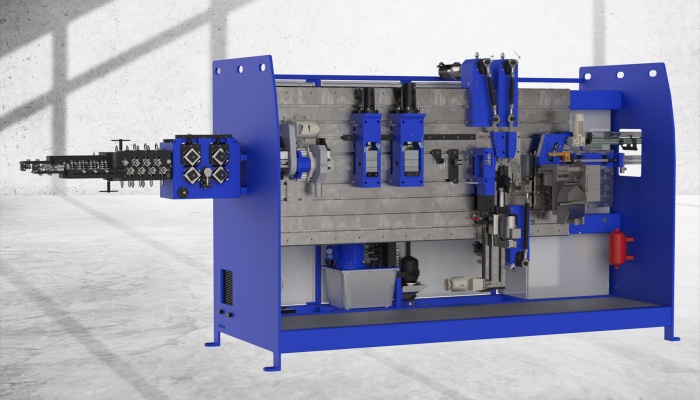

The ABM 320 is specially designed for paint roller handle production with a wide range of forms, sizes and wire diameters. Wire uncoiling via driven coil holder, wire straightening and wire pressing have been taken over from the previous machine model. Newly designed is the bending technology with three servo driven cams, effectively doubling the machine performance!

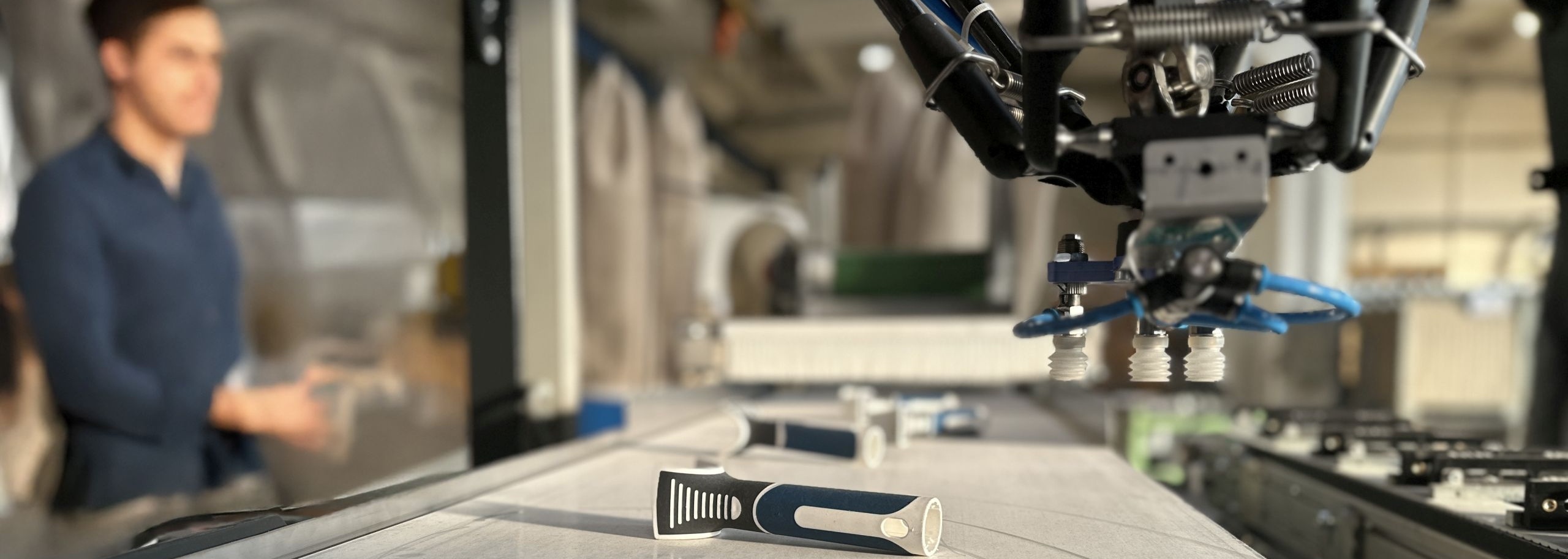

The wire is pulled off from the driven coil holder throught a double plane straightening device and length measuring system. The so called wings for holding the plastic handle are pressed, the plastic handles fed from the other side and assembled on the wire. Finally the bending process is made in 3 steps in rapid sequence and the finished paint rollers are ejected.

Features

- Quick setting change-over

- Manual or automatic handle feeding

- All wire forms

- High performance

- 11" touch screen

Modules

- Driven wire coil holder OZD 1500 - for automatic wire feeding from coil with infinitely variable speed control.

- Wire straightening device.

- Wire feeding device (accuracy ± 0.5 mm).

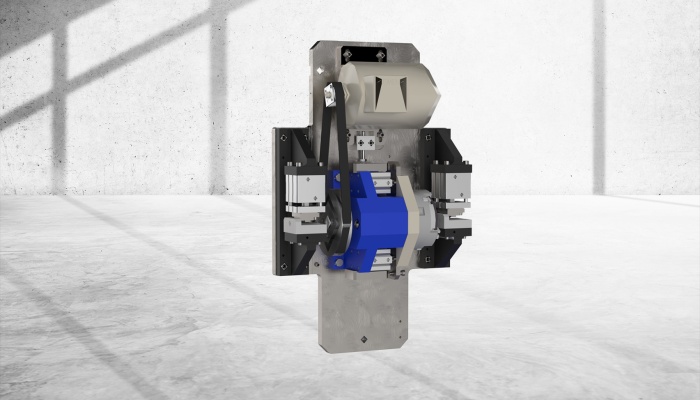

- Hydraulic ‘wing‘ forming and cutting device.

- Bending unit with 3 cams and servo drive.

- Chamfering device.

- Vibration magazine for separation and transport of plastic handles.

- Optional step feeder with conveyor for feeding the handles into assembly position.

- Assembly device with ejection.

- Further options like grooving, threading, labelling.

Technical data

| Capacity | approx. 35 - 40 pieces/min. (2,100 pieces/h) |

| Wire strength | max. 650 N/mm |

| Wire diameter | 6 - 8 mm (0.24 - 0.32"), galvanised steel wire, other diameter on enquiry |

| Wire coil | max. 1,500 kg |

| Types of handles | to customer requirements |

| Hydraulics | 20 MPa |

| Air pressure | 0.6 MPa |

| Air consumption | max. up to 17 m³/h |

| Sound level | 75 dB - measured at distance of 1 m to machine |

| Height | approx. 2,200 mm |

| Weight | 3,900 kg |

| Area required | approx. 7,000 x 2,000 mm |

| Electrical connection | 3 x 400 V/50 Hz, N/PE, 17 kW |