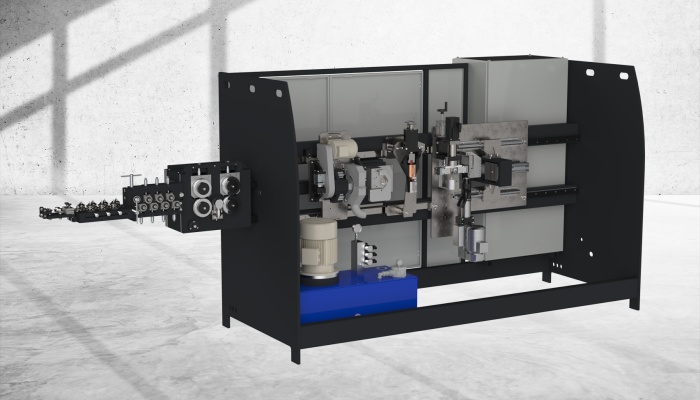

ABM 100 - Frame bending machine

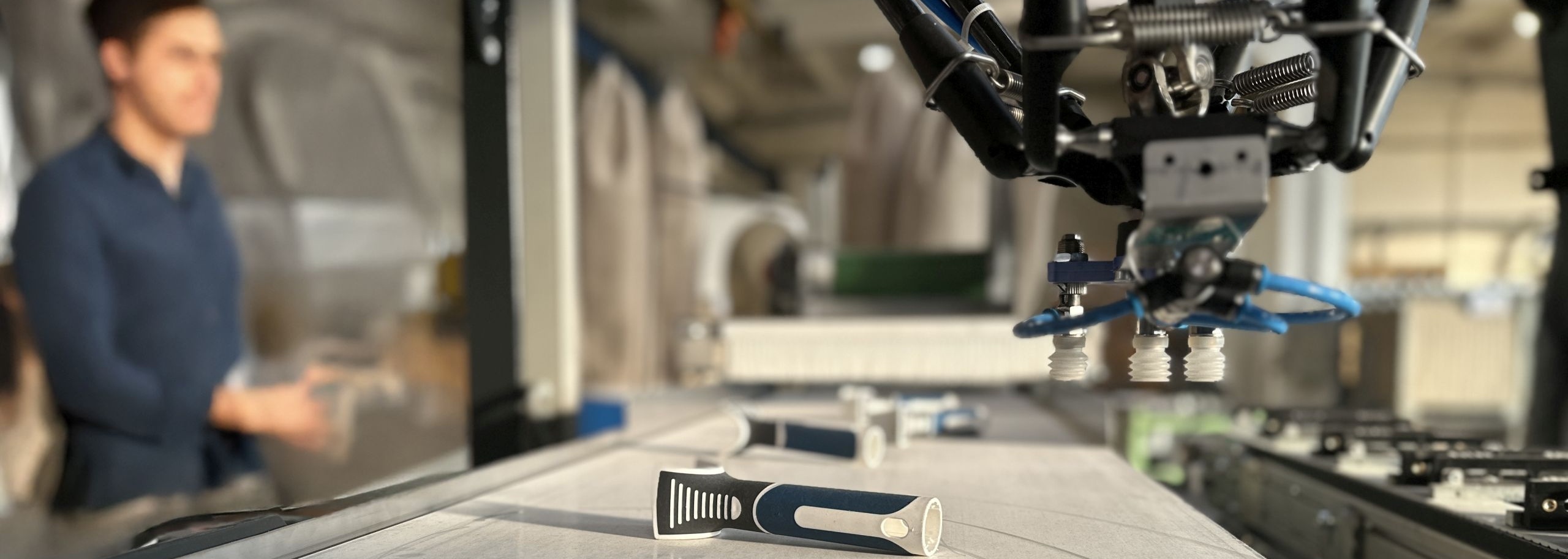

The Automatic Paint Roller Handle Machine is designed for the production of wire frames and their subsequent assembly together with plastic handles for paint rollers. The machine allows paint roller handles to be produced in various sizes and wire diameters.

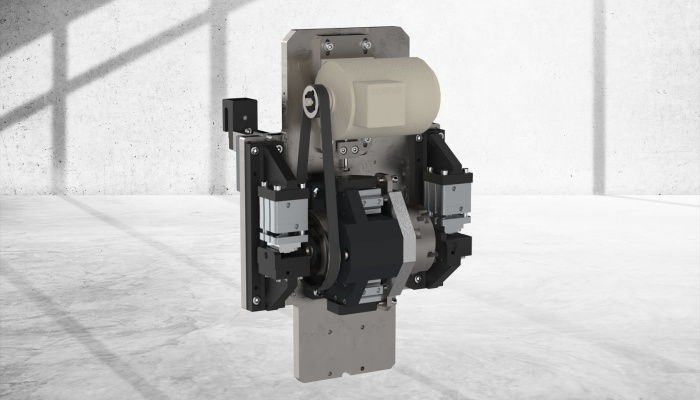

The wire is taken off from a driven coil holder through twin-plane straightening rolls and into the feeding and length measuring system. The wire is fed and measured by two pairs of grooved rolls. Feed accuracy is ± 0.5 mm (0.02"). The cutting and forming of so called „wings“ for fixation of wire in handle are performed by a hydraulic device. The final shape of wire is bent by means of aservo motor, based on the method of free programmable step by step bending. Between two subsequent bending steps there always follows an accurate wire feeding. The programmable unit allows to change an angle and a length of feeding, driven by a servo motor, 3,5 kW, 4500 rpm. After bending follows transferring to the position for assembly together with the plastic handles. The machine runs in fully automatic cycle with production output approx. 17 – 19 handles per minute, depending of shape and length of handle type to be produced.

Changeover time different wire frame within the same wire diameter: 30 minutes.

Changeover time from between different wire diameter and wire frame: 4 hours.

Features

- Universal production of all wire frames.

- For two wire diameters.

- Quick setting change-over.

- Manual or automatic handle feeding.

Modules

- Powered wire coil holder – ready for automatic wire feeding to machine, with variable acceleration and deceleration of speed and external start stop function.

- Wire processing machine, i.e. Straightening device Feeding device (± 0,5 mm) Forming and cutting device – driven by hydraulics Bending unit - by servo motor Pointing – chamfering device - mechanical.

- Vibration magazine for orientation and separation of plastic handles, optionally with conveyor belt for plastic handle supply in mounting position.

- Assembly unit with ejection – electrical and pneumatic.

Technical data

| Capacity | approx. 17 - 19 pieces/min. |

| Wire strength | max. 650 N/mm |

| Wire diameter | 6 - 8 mm (0.24 - 0.32"), galvanised steel wire, other diameter on enquiry |

| Wire coil | max. 1.500 kg |

| Types of handles | to customer requirements |

| Hydraulics | max. 200 bar |

| Air consumption | min. 6 bar |

| Area required | approx. 3.6 x 2 m (12 x 7 ft) |

| Electrical connection | 17 kW, 3 x 400 V, N/PE, 50 Hz |