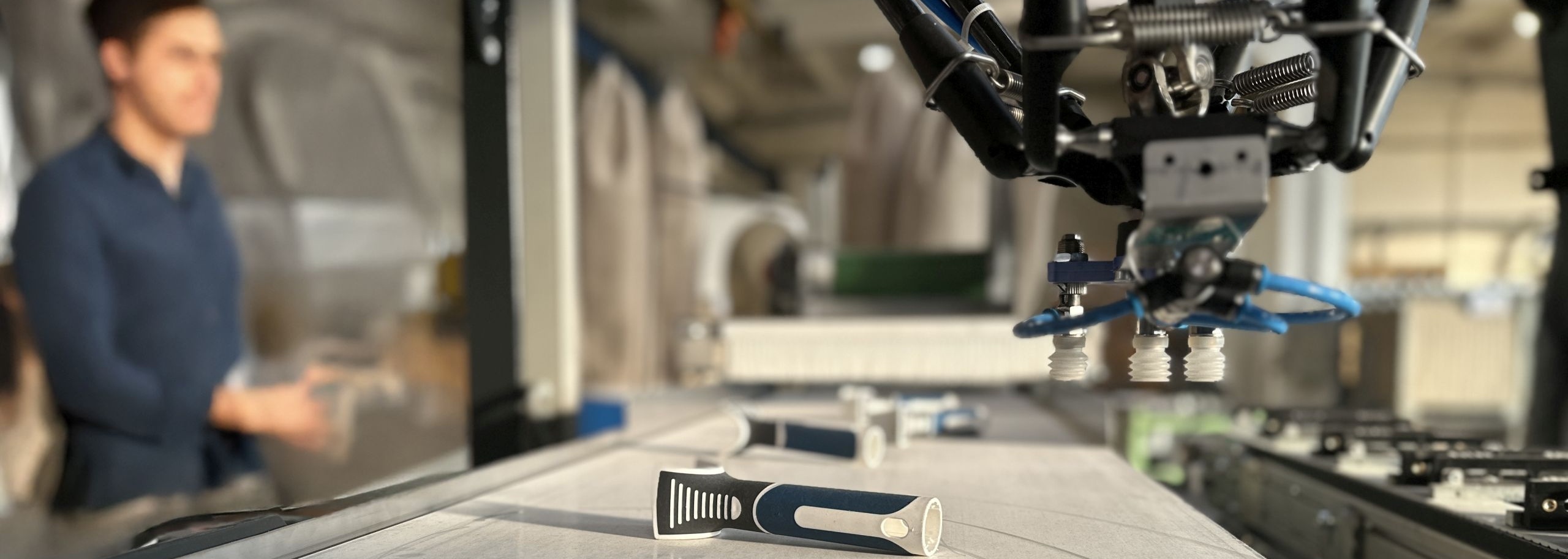

FCA - Core assembly

Characteristics

Specially designed for the automatic assembly of roller cores, consisting of various length tubes, plastic bearings and caps. The single parts are continuously separated in vibration hoppers and fed on to the assembly points. The tube is fed first and its proper position determined by a laser light scanner. The plastic bearings are then separated and inserted into the tube. A further station checks the presence of the bearing in the tube, rejecting any tube if missing. On the following station the caps are fed by a sorting device and pressed in the tube. A final control of the assembled parts is made on the last station.

Features

- High flexibility

- High capacity

- Short change-over time

- High reliability

Technical data

| Capacity | max. 3,600 pieces/h, depanding on tube length |

| Pneumatics | 0.6 MPa |

| Sound level | approx. 75 dB |

| Area required | approx. 2.1 x 1.3 m (6.8 x 4.26 ft) |

| Weight | 600 kg |

| Electrical connection | 3 x 400 V/50 Hz, N/PE, 2.5 kW |