FDA - Drilling Machine

Characteristics

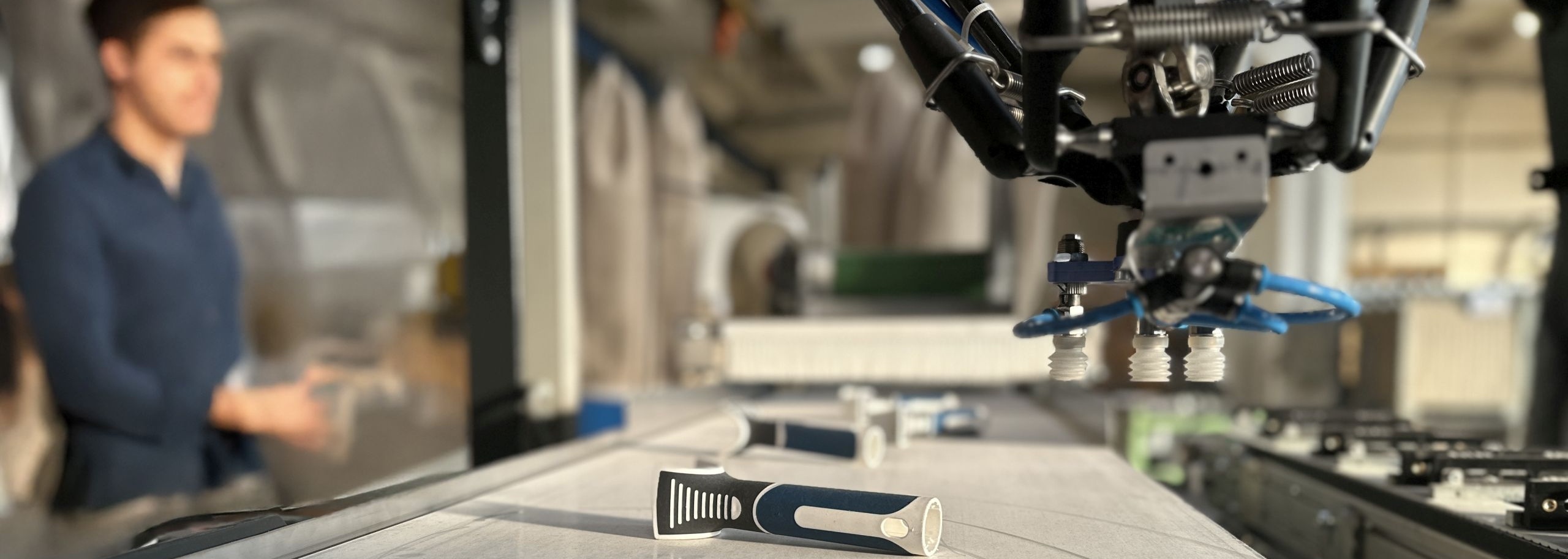

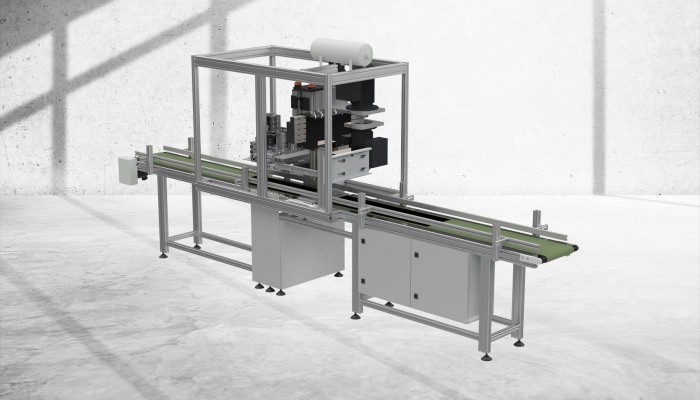

- The foam block is put onto the conveyor belt and pulled-in by the machine

- in the spraying unit the surface of the foam block is sprayed with a non-silicone-containing slip additive

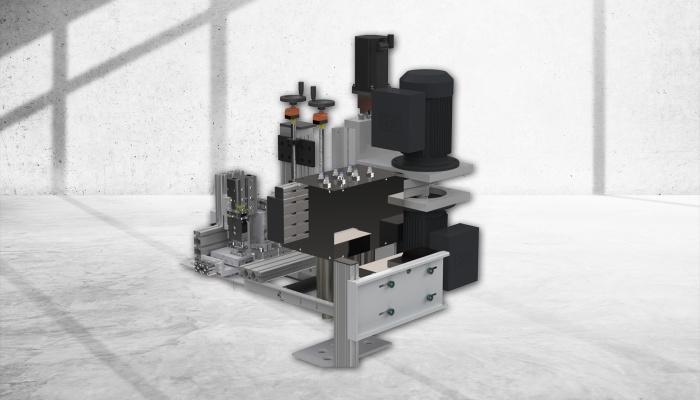

- interior and exterior diameter of the roller are being drilled at the same time

- in case of a drilled through interior diameter the cores could be blown out in this unit

- in the pluck-out unit the inner cores are being torn out and ejected

- at the removal unit the drilled holes must be controlled and the foam block can be transported on to a gluing machine connected thereafter via a roller transport

Features

- maximum economy

- high flexibility

- simple operation

- high capacity

- production security

- very low change-over time

Technical data

with roller length 100 mm

| Capacity | up to 3000 resp. 6000 rollers per hour* |

| Material dimensions |

height max. 185 mm (7.28") width 300 mm resp. 500 mm (11.8" resp. 19.7") length 2500 mm (98.4") |

| Drill |

ext. diam. 34 - 38 mm (1.34 - 1.5")** int. diam. 14 - 18 mm (0.55" - 0.71")** |

| Drives | infinitely variable |

| Power supply | 400 V / 50 Hz |

| Air supply | 6 bar |

| Control | pulse motor control with PLC and touch screen |

* depending on the material, foam block width and roller length

** different diameters upon demand