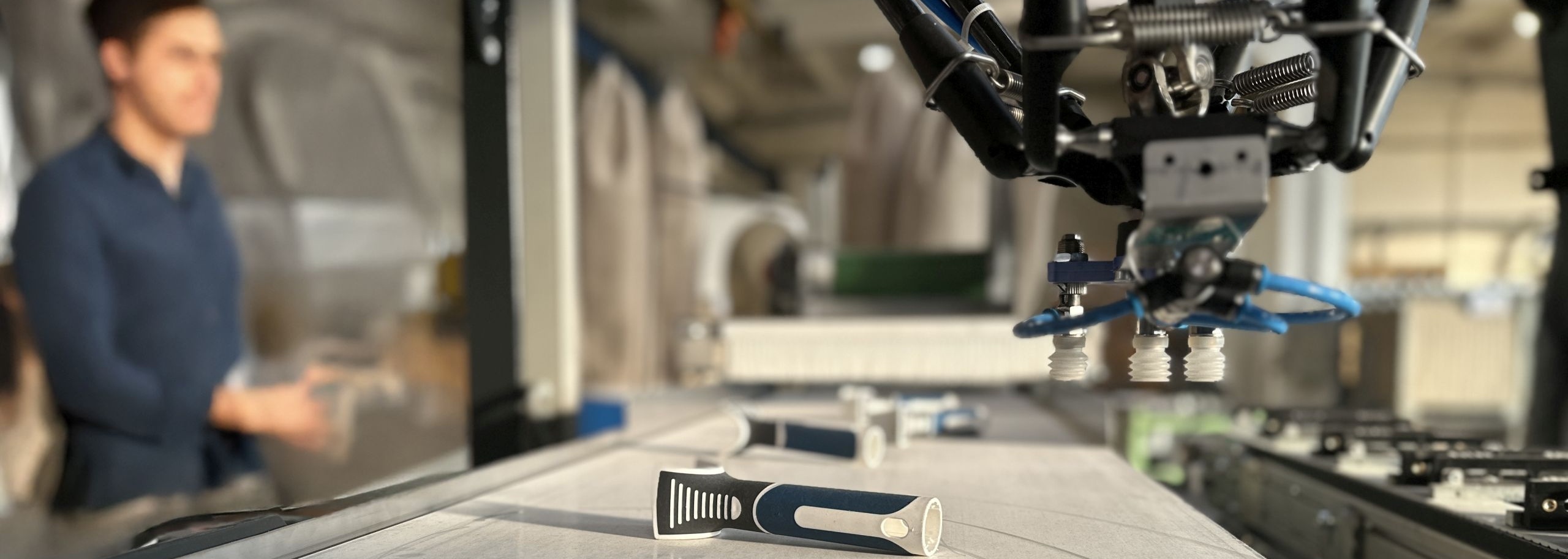

RMA 100 - Semi-automatic assembly machine

Characteristics

It is a semi-automatic machine for the brushing and assembling of plush paint rollers.

The paint roller and plastic parts are manually placed on the mandrels of the rotary horizontal carousel by an operator and is transported to the following working position on the carousel.

This is followed by brushing of the paint roller. The brushing is provided in one station by two punched brushes made of polyamide fibres. One brush is fixed and the second one is movable. For each brush it is possible to set the speed, direction of rotation, brushing time and depth of brushing. Both brushes can be switched on / off independently of each other. The brushing time of the fixed brush can be affected by the skill of the operator (it depends on the speed of placing the roller and plastic parts on the mandrel).

In the next step (position) the plastic caps are pressed on both sides of the paint roller. Pressing is provided by a pneumatic cylinder. After the finishing of these work operations, the roller is automatically thrown into the chute and falls into a transport box.

Features

- Simple operation

- High flexibility

- Maximum economy

Technical data

| Cycle time | 1200 /h psc/hour (according the brushing time and operator skills) |

| Roller length | 180 - 280 mm (7.1" - 11.0") |

| Roller outside diameter | 40 - 120 mm (1.6" - 4.7") |

| Compressed air | min. 6 bar |

| Air consumption | max. 34 m3/hour |

| Dimensions | 1080 x 1350 x 1980mm (3.54 x 4.43 x 6.50 ft) |

| Weight | cca 350 kg |

| Electrical connection | 1 kW, 230/400 V, N/PE, 50 Hz |