RWM 100 - winding machine for radiator rollers

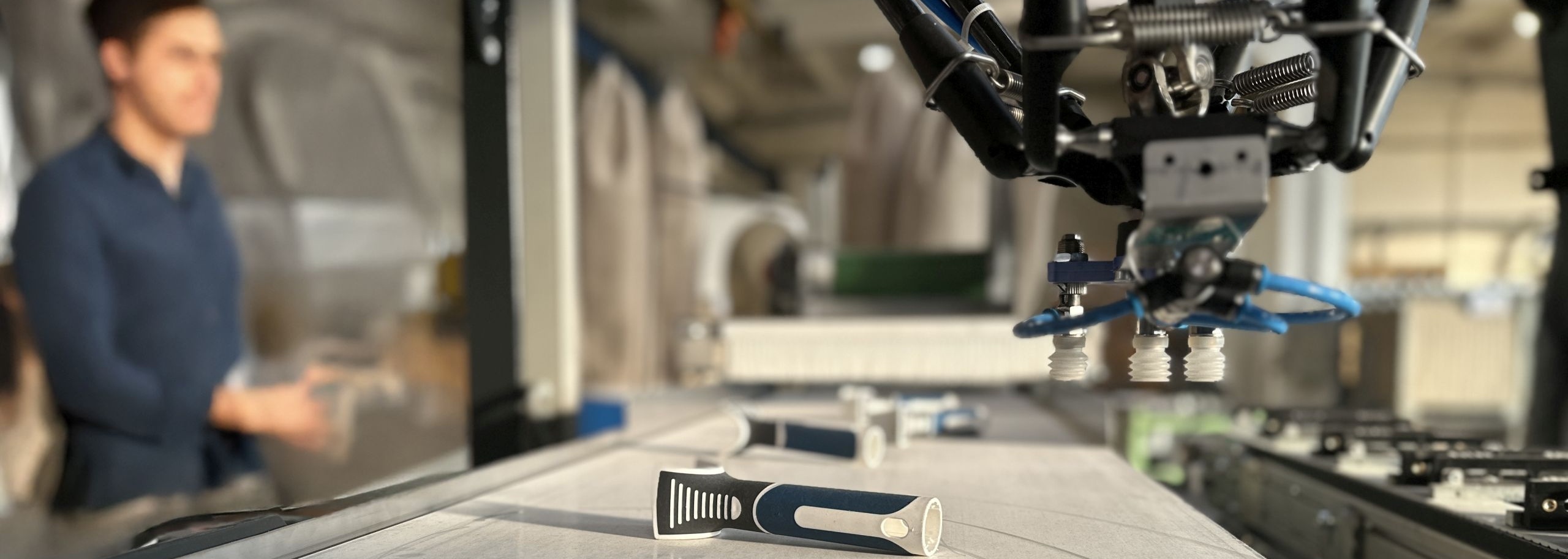

For winding all available plush mini rollers.

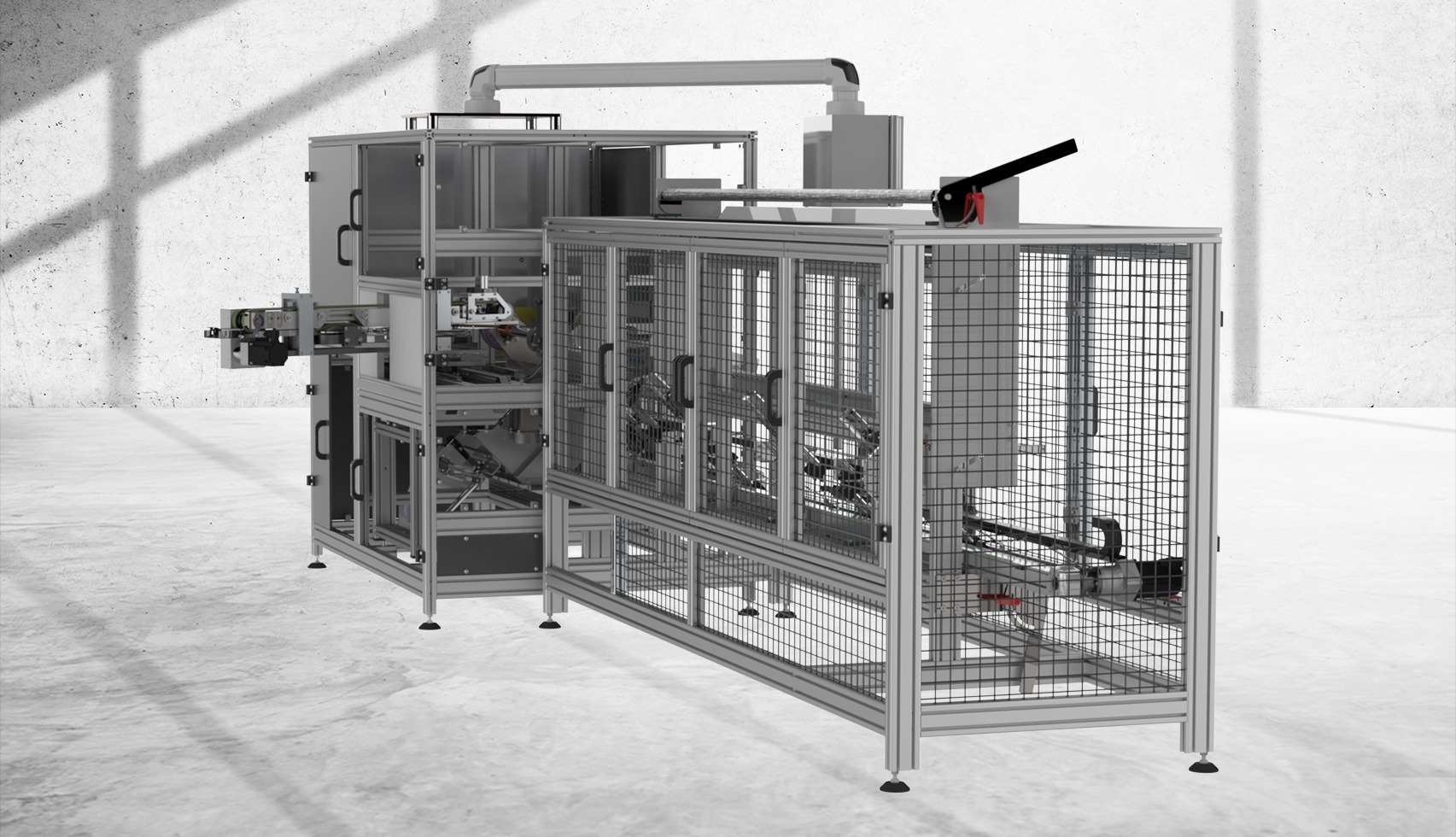

- via the feeding unit with tube magazine the tubes are transported to the rotating plate with 4 roller mandrils

- optionally a tube bar magazine with cutting device can be installed here

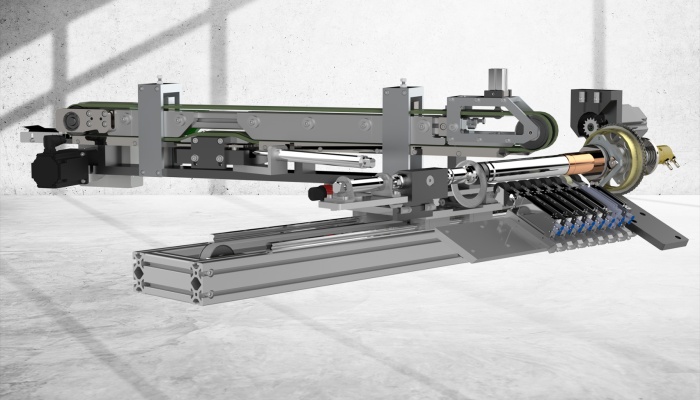

- in the heating unit the surface of the plastic tubes is heated up by means of a gas burner

- in the winding unit the plush is fed automatically, the tube is wound and cut into the programmed length

- the joining of the plush with the tube is done by first melting the surface and then cooling it off

- this way the back of the plush combines with the tube mechanically

- after that they are removed by means of a transportation belt or are fed into a connected assembly machine

- with exchanging tools the machine can quickly be changed to various lengths and diameters

Features

- maximum economy

- high flexibility

- simple operation

- high capacity

- production security

- very low change-over time

Technical data

| Capacity | up to 600 rollers/hour* |

| Tube measurement |

length min. 100 mm (4.0") length max. 300 mm (11.8") diam 13 - 30 mm (0.5"-1,8") |

| Power supply | 400 V / 50 Hz |

| Air supply | 6 bar |

| Gas supply | working pressure 30 - 70 mbar propane or natural gas |

* depending on the length and diameter of the tube and the kind of plush