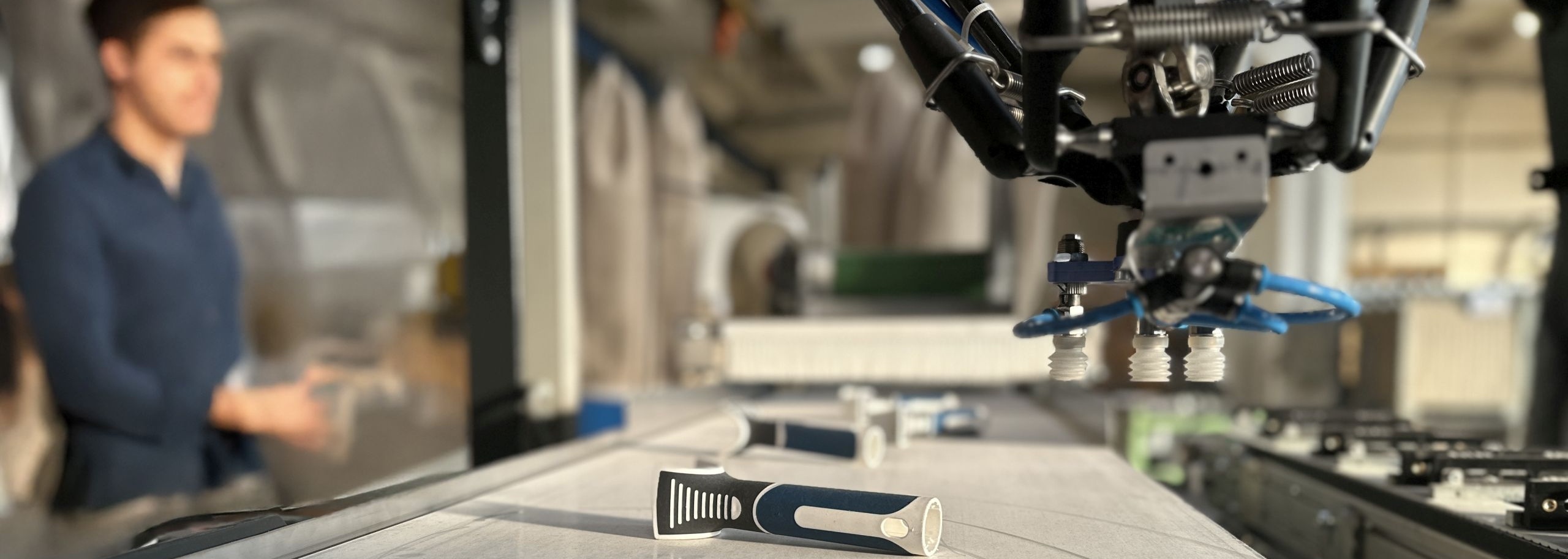

RCA 200 - Paint roller assembly automat for MIDI Rollers

The machine consists of two carousels and one transfer station, three vibratory hoppers and a long tube magazine. Each carousel can have up to 10 stations. The rollers can be made closed (folded) from one side, or not closed then caps are pressed from both sides. The machine is equipped with a very sophisticated control system with graphic control. The machine is designed for processing and assembly of medium size rollers (MIDI).

The machine cuts the rollers from the long tube to a certain length, sorts off the cuttings, then brushes, chamfers from one side and then from the other side. After that the rollers are handed over to the second carousel, where the assembly gets on with the cap, adapter and clamp (bearing). Next the roller is brushed up and finally ejected from the carousel. Each carousel can have up to 10 stations, which can be fitted according to the customer's wishes.

Features

Powerful and reliable.

- Great efficiency

- High production capacity

- Integrated remote management

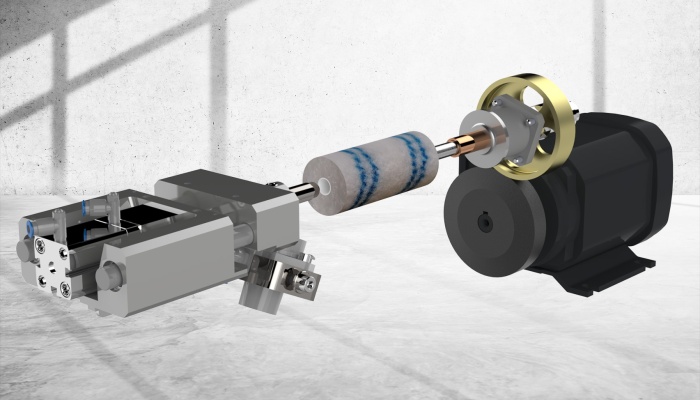

The machine consists of individual stations

- Cutting the tube

- Sorting of residues

- Brushing

- Chamfering from one side

- Chamfering from the other side

- Assembly of adapter with clamp (bearing)

- Heating

- Assembly the adapters in the roller

- Assembly the cap

- Brushing

- Ejecting

Also, assembly the adapter with the clamp (bearing) does not always have to take place directly on the machine and this operation can be performed on another device.

Technical data

| performance | up to 1000 pcs/hour, depending on size and quality components |

| length of the final roller | 60 - 160 mm (2.36" - 6.3") |

| tube length | 1100 - 3000 mm (43.3" - 118.1") |

| inner diameter of the roller | 14 - 30 mm (0.55" - 1.18") |

| control | industrial PC with touch screen |

| electrical connection | 400 V / 50 Hz (60 Hz) |

| compressed air | 6 bar |

CE safety standard.

Machine is for 1 interior roller diameter.