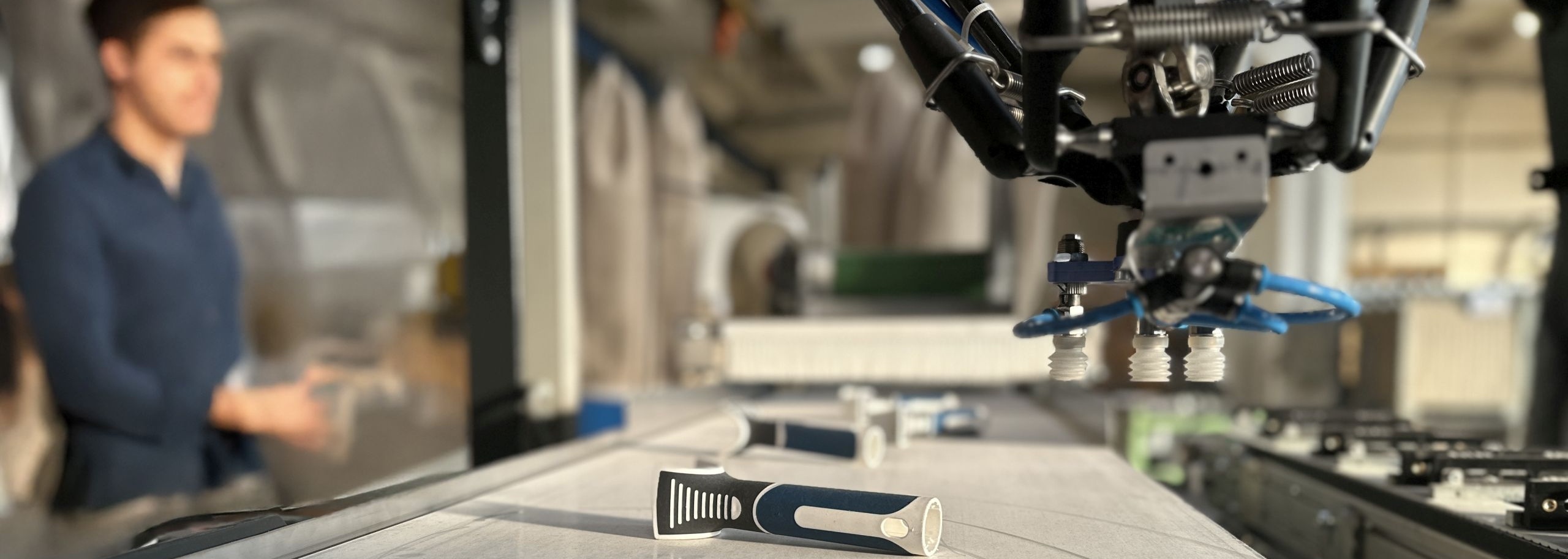

PCM - Plush strip Cutting Machine

For cutting all available plush and lambskin material.

Comprising

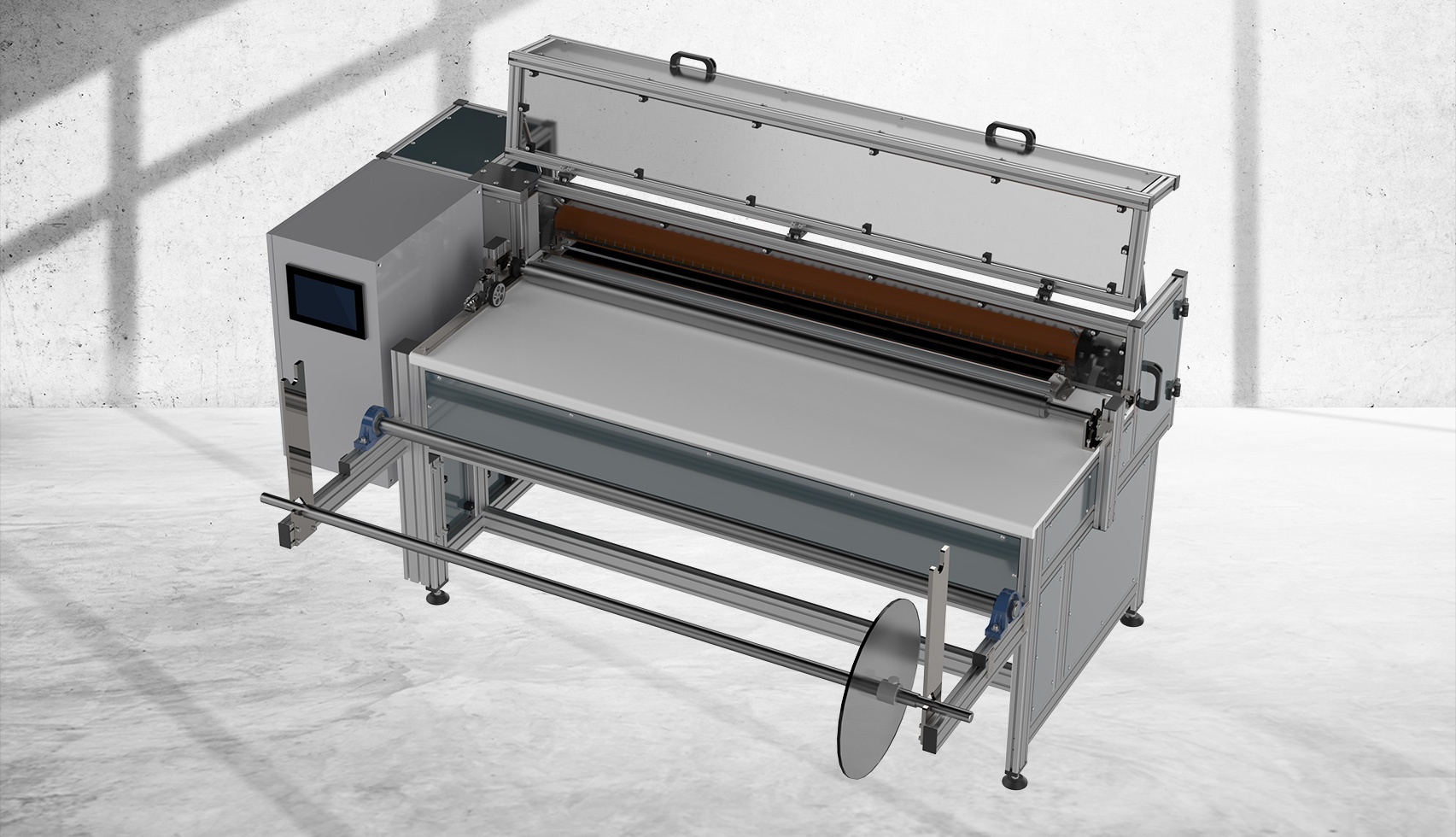

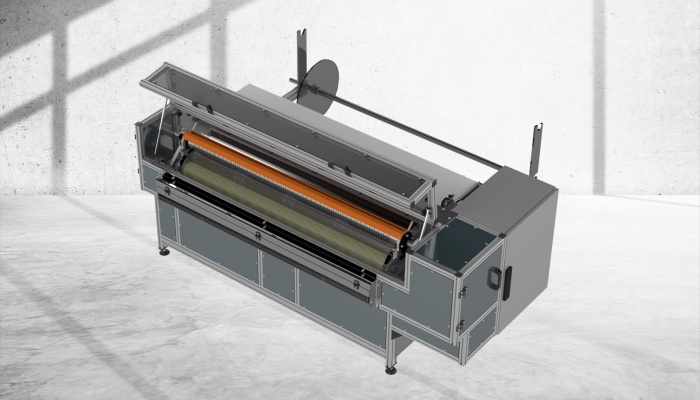

- Plush or lambskin is supplied to the cutting unit via the supporting table.

- There is a possibility of installing a belt guide here for straightening the material.

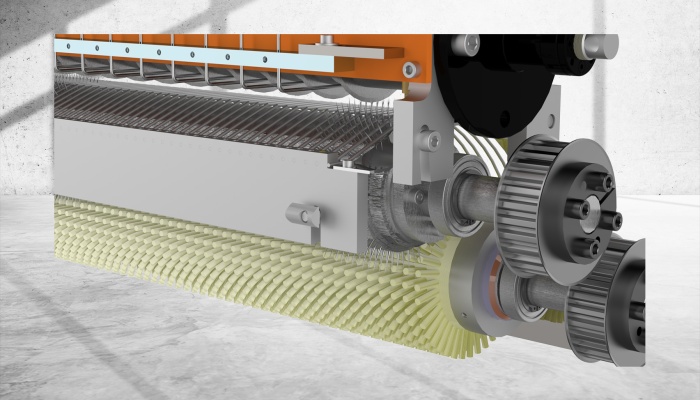

- The material is seized by a needle drum and cut.

- At the end the cut material is deposited on the plaiting table or is rewound to coils by means of a winding equipment.

- The cutter bar, equipped with round blades, is rapidly exchangeable and furnished with a corresponding drive.

- Cutter bars are available for fixed and variable strip widths.

- If there are several cutter bars a revolving device for faster change-over of the blades is recommended.

Features

- maximum economy

- high flexibility

- simple operation

- high capacity

- production security

- very low cleaning time

Technical data

| Cutting capacity | 3 - 15 m/min (9.8 - 49.2 ft/min) |

| Width of cutting | max. 1600 mm (max. 63") |

|

Depth of cutting (= depth of penetration of the blades into the feed unit) |

16 mm (0.63") |

| Bale diameter | max. 800 mm (max. 31.5") |

| Width of bales | max. 1700 mm (max. 67") |

| Power supply | 400 V / 50Hz |

|

Total connected load (without winder) |

ca. 3,5 KW |

*depending on the quality of the plush