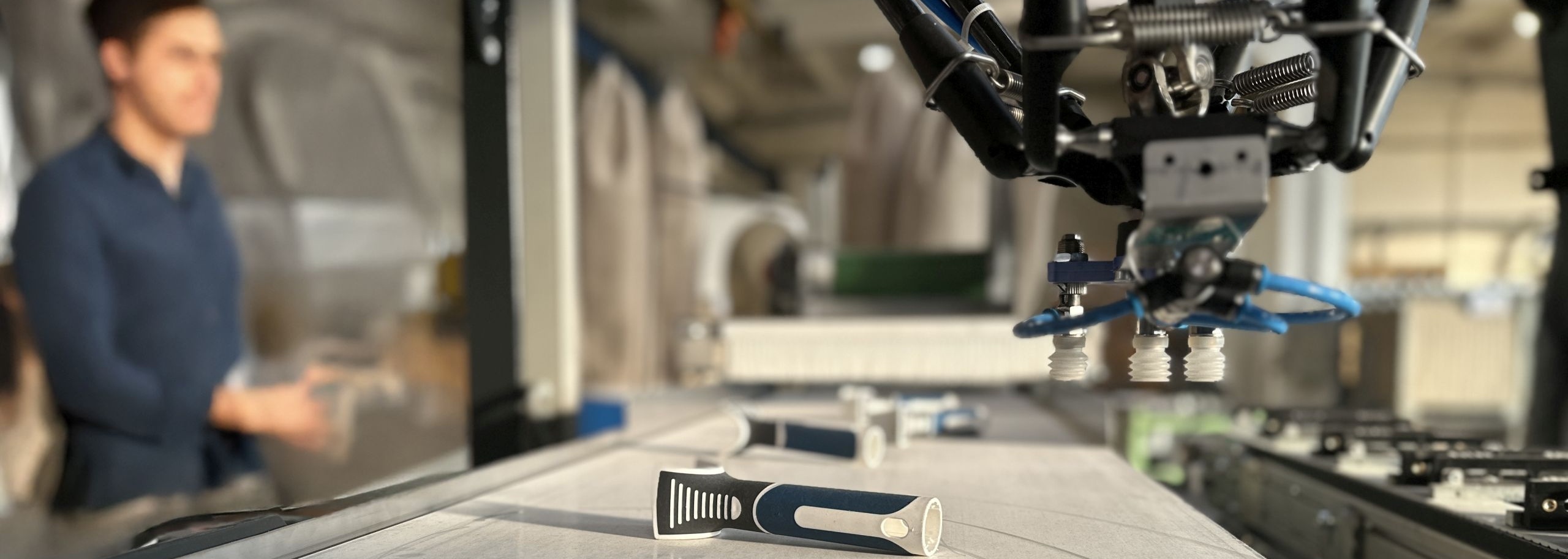

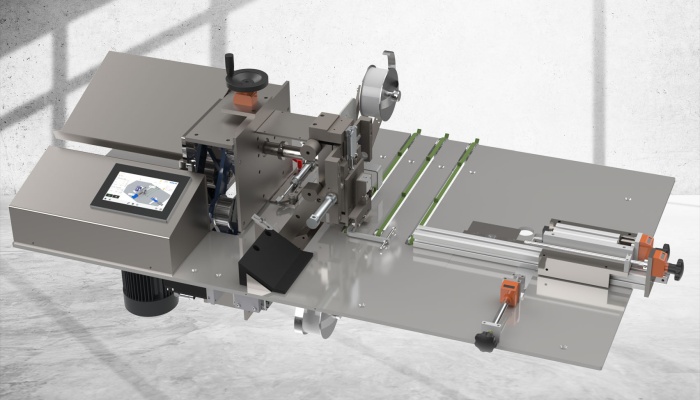

PIM - Flat paintbrush handle inserting and stapling machine

Characteristics

- The brush-head is fed from an adjustable magazine and clamped simultaneously.

- The brush-handle is pushed into the brush-head from and adjustable magazine.

- The paint brush is stapled by two aggregates working simultaneously from the top and the bottom.

- The brush is shifted and stapled again (Up to max. 4 staples possible).

- The brush is transported from the machine by means of an integrated conveyor.

- If required the brush can be printed in the machine (tampon-, hotprint-, thermo-transfer- or ink jet printer).

Features

- maximum economy

- high flexibility

- simple operation

- high capacity

- production security

- very low cleaning time

- low cost production of the staples from wire coil

- continuous setting of staple distance

- choice of brush program from a touch screen

- option: integrated printing-equipment, installation of a packing machine

Technical data

| Capacity | up to 2000 brushes per hour* |

| Dimensions of brushes |

width of brushes 15 - 100 mm thickness of brushes 6 - 25 mm |

| Power supply | 400 V / 50 Hz |

| Control | pulse motor control with PLC and touch screen |

| Total connected load | 0,75 KW |

| Air supply | 6 bar |

| Size of staples | 5 x 5 x 5 mm |

| Distance between staples | max. 60 mm |

| Size of wire | 0,9 x 0,65 mm |

* depending on the skill of the operator resp. on the amount of staples required