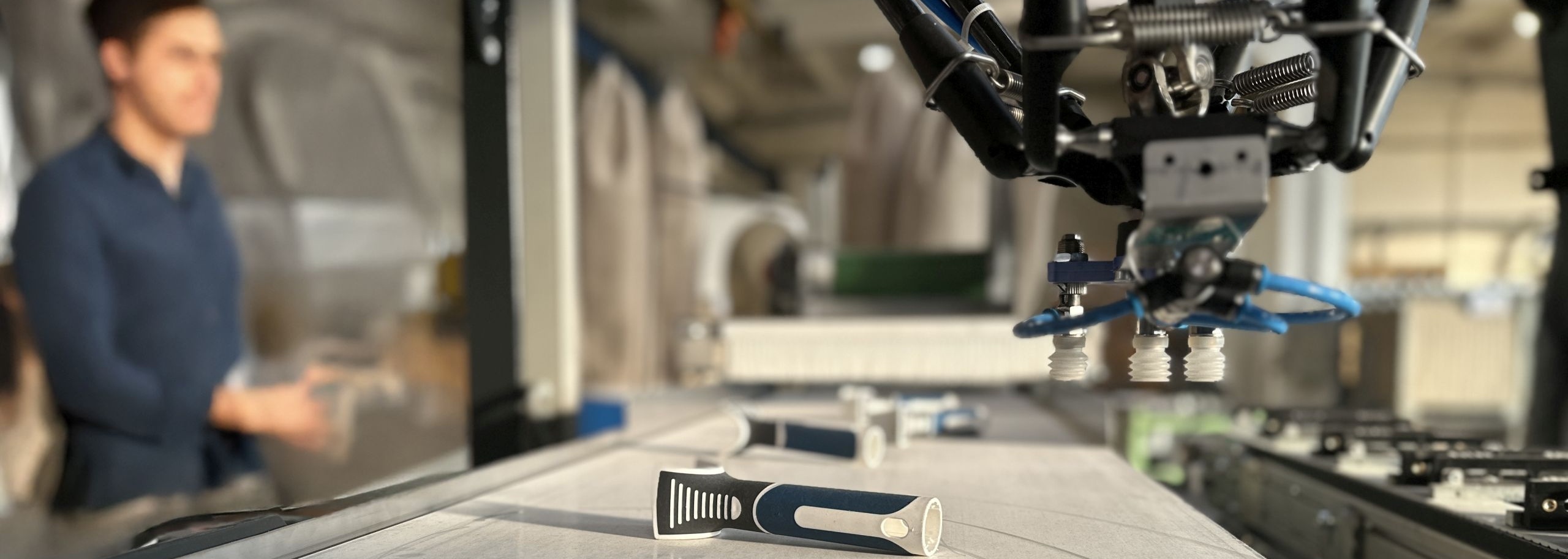

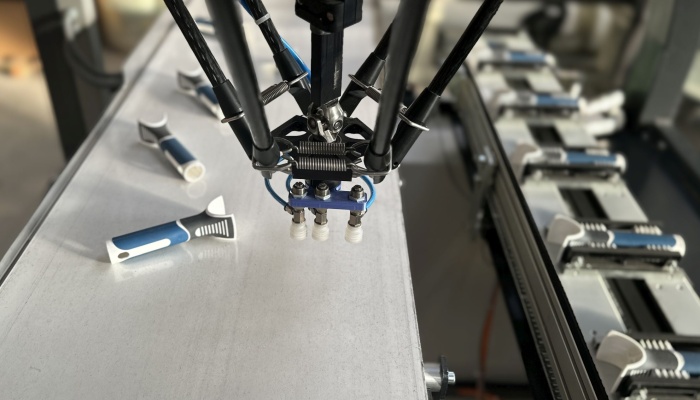

RHO 100: Automated Handle Orientation

Automated Handle Orientation Speeds Up Paint Roller Production

WÖHLER's latest innovation, the RHO 100 machine, enhances paint roller production efficiency through its automated handle orientation system. Employing a robotic tripod, the RHO 100 accurately and consistently positions oriented handles on the conveyor belt, significantly boosting productivity and reducing labor costs.

Flexibility and rapid readjustment

"The RHO 100 is particularly advantageous for customers handling a wide variety of paint roller holders," explains CEO Jaroslav Markvart. "Its rapid mechanical readjustment, achievable within minutes, enables flexible production without the need for large, costly inventories."

Processing speed up to 1.2 rollers per second

As a compact extension of WÖHLER's ABM 320 wire bending and attachment machine, the RHO 100 completes the automatization of the paint roller production, processing up to 1.2 rollers per second. For added convenience, an optional labeling unit can be integrated at an affordable price.